- Pack size

: Type C(1060x630x300), water cooling, MSD

- Applicable cell

: SDI 4695, 3.65V, 34.2Ah / 125Wh, 450g

- BMS composition

: CIC(Cell Info Collector), Local Master, System Master

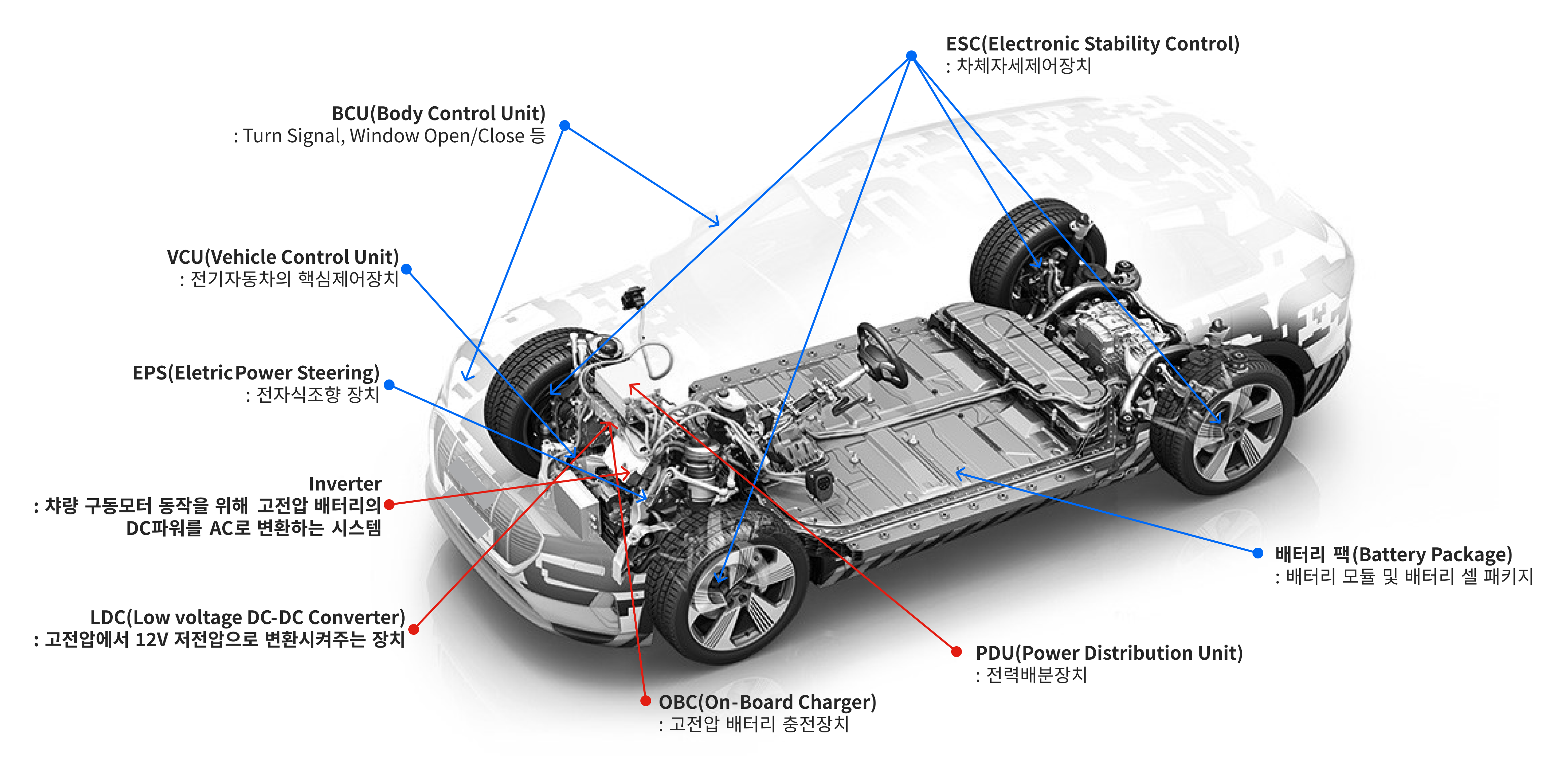

: Software Defined Vehicle

: Providing and analyzing vehicle management/services optimized for electric vehicles

: Standard mobility platform based on reliability and stability

: A system that monitors the battery's condition and controls it to the optimal state.