prev

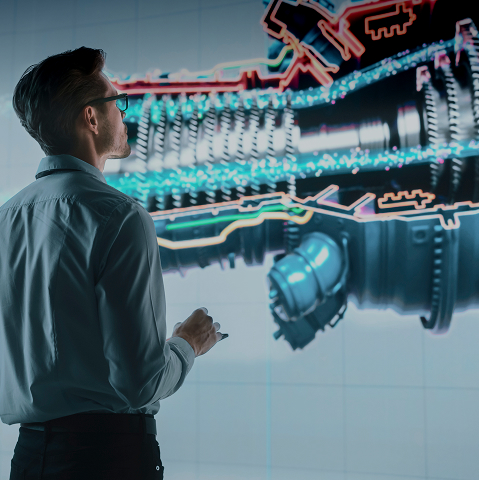

Quality Reliability

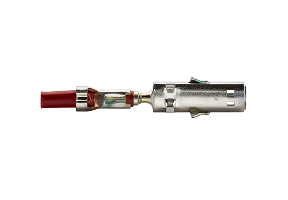

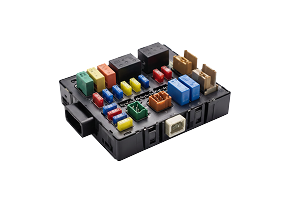

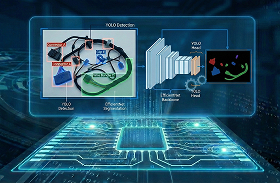

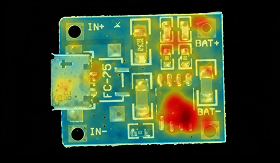

AI-based visual inspection detects tiny defects, contamination, and deformation Automatically detects defects and strengthens harness quality reliability

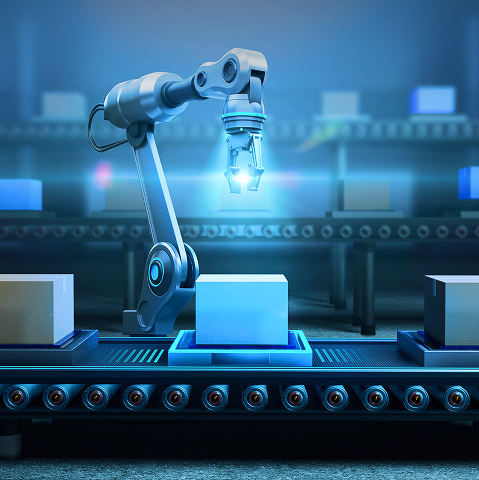

Inspection Efficiency

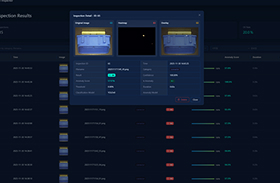

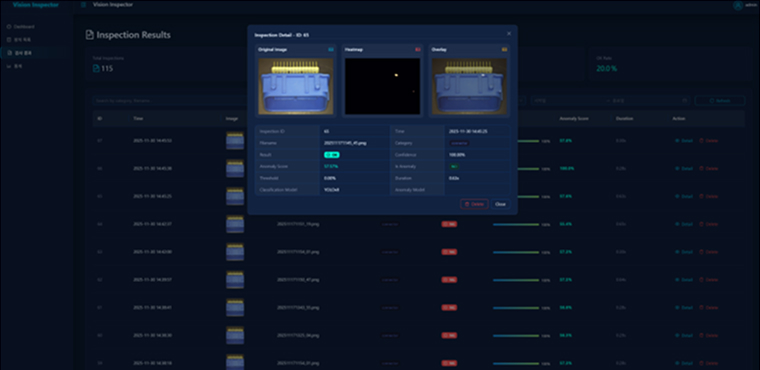

Compared to traditional inspection, dramatically reduces inspection time Automates repeated and labor-intensive inspection work, improving efficiency

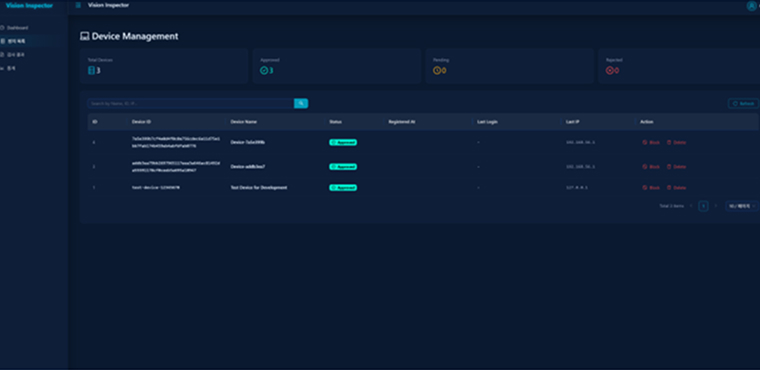

Quality Management System

Inspection results are automatically collected and analyzed Allows defect statistics and root-cause analysis

NEXT

Long inspection time

Long inspection time

High manpower dependency

High manpower dependency

Quality control limitations

Quality control limitations